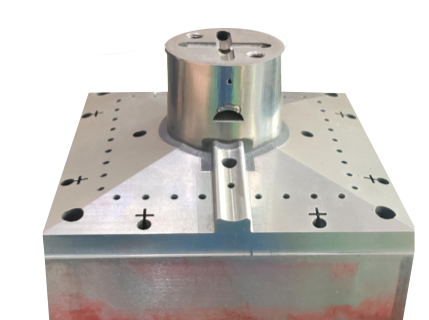

Available Now For New Molds or Upgrades and Retrofits

Production Perfection

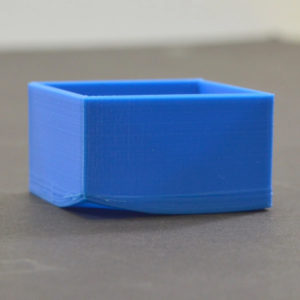

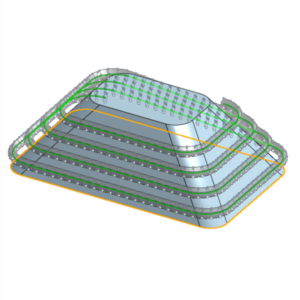

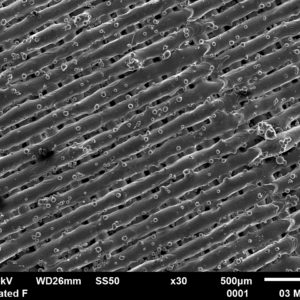

Since the invention of the samurai sword in the 13th century engineers understood the importance of heating and cooling to ensure extraordinary performance. Today, CoolToolTM delivers the #1 high volume part production processes for plastic injection molding. Our technology utilizes proprietary predictive modeling, design, and additive manufacturing techniques to bring conformal cooling technology to scale.

Today, we deliver the fastest turnaround on the most complex, high-volume production parts for plastic injection molds. Our CoolToolTM solution is also hassle-free and non-disruptive to current plastic injection molding sourcing and technology.

CoolToolTM Revolutionizes Plastic Injection

Molding in 3 Ways

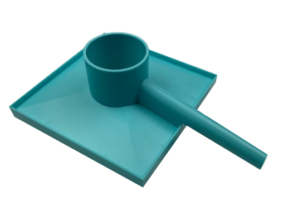

For Product Innovators

1. Faster go-to market times

2. Reduced costs

3. Improved part quality

For Contract Manufacturers

1. Additional capex utilization

2. Improved margins

3. Less scrap

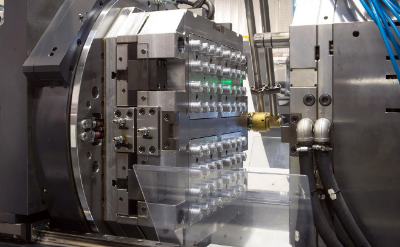

Common Injection Molding Problems.

Sink Marks

Warping

Burning

And how CoolToolTM Solves Them.

Sink Marks

Embedded Heat Syncs

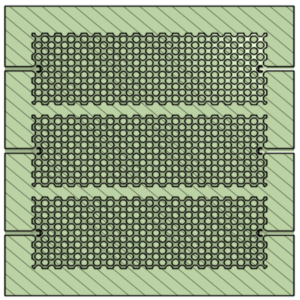

Precision Porosity & Venting

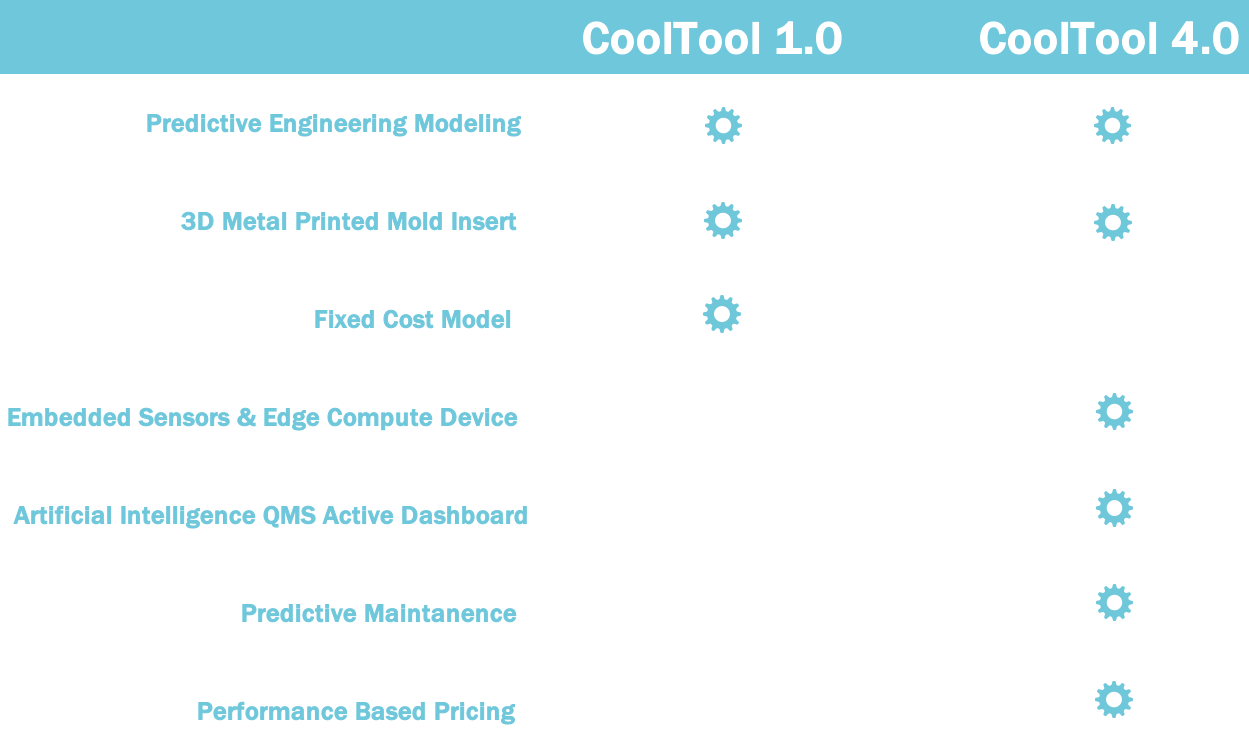

Industry 4.0 Platform

Innovative Pricing Model

See How Much You Can Save with CoolToolTM

Schedule a consultation with our team,

or submit your project details for a full RFQ here.