The focus of CoolTool innovation is on the design of the injection mold insert. By improving the mold insert itself, this technology can be integrated directly into any injection mold tool for any injection molded part. This allows for the industry standard injection molding process to proceed as-is. Except of course for the substitution of the 3D metal printed CoolTool mold insert for the existing milled mold insert. The CoolTool insert is intentionally designed to be “plug-and-play.”

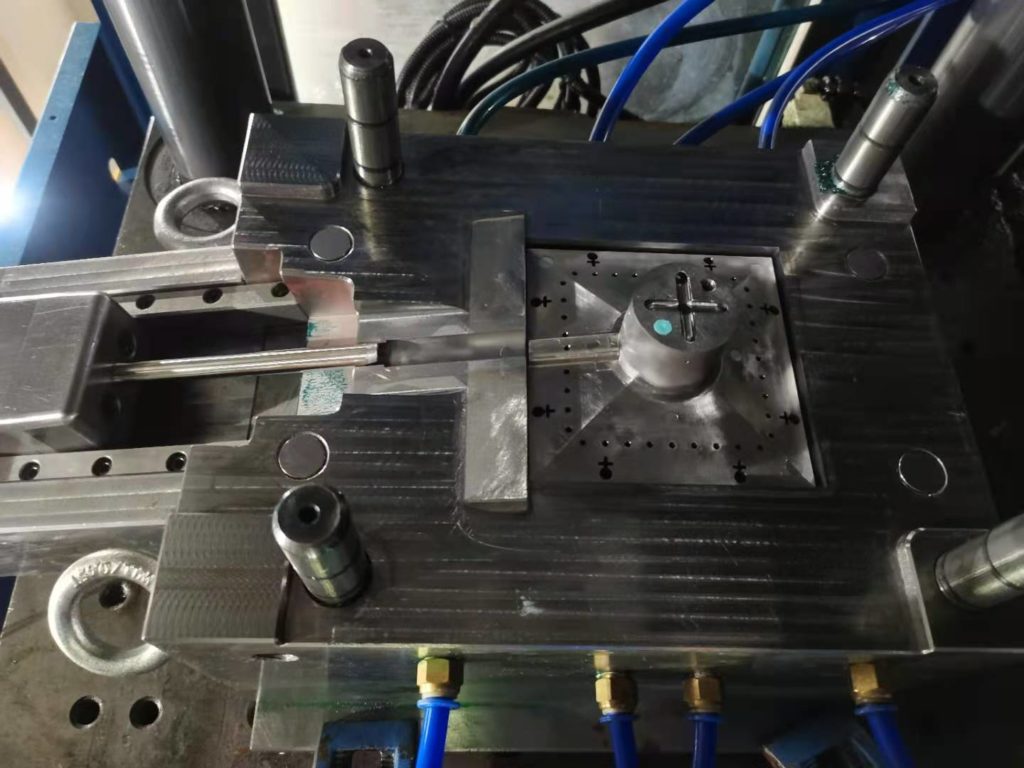

For integrating the CoolTool into an injection mold process, the first step is to examine the current mold design and associative constraints of the injection mold machine and injection mold base. This includes: locations of the ejector pins, shutoffs for split-lines, threaded fastening locations, and other tight tolerance locations. Within these design constraints the cooling lines are not placed within 1mm of any part geometry of the insert. By identifying and incorporating design constraints of the entire injection molding process at the onset of a project, CoolTool ensures an error-free integration. This means that the optimized mold insert still has the same installation steps as the original mold insert.

Surface finishing processes are often considered integral. The CoolTool design process takes the surface finish of the mold insert into consideration. Utilizing different texture processing techniques, the ideal texture and roughness of the mold surface can be accomplished as defined by the customer. This ensures that the quality of the finished parts produced by the CoolTool mold meets or exceed customer specifications.

Most importantly, the cooling process and CoolTool derived performance integrates into existing cooling manifold setups. Cooling lines are designed to be threaded with traditional assembly processes.

Throughout the design process, ease of integration on the client’s end is constantly considered. All these considerations allow for an invariable installation process for the CoolTool compared to the original mold insert.